Custom rubber floor mats protect flooring and can reduce the risk of employee injuries. In the heavy equipment industry, these industrial rubber products are used in the cabins of forestry, mining, construction and agricultural equipment. Custom rubber flooring is easier to clean and maintain than carpeting and won’t wear as easily from repeated contact, such as with an operator’s boots. Plus, it can be combined with thermal or acoustic insulation to reduce cabin heat or noise.

Elasto Proxy prides itself on putting you in the driver’s seat with our value-added sealing and insulation solutions. We also make sanitary floor mats for food processors and commercial kitchens, anti-fatigue mats for companies where employees stand for long periods of time, and rubber flooring that is custom-cut or comes in sheets or rolls. The products we supply are easy-to-install and they’re made especially for your application.

Keep reading to learn about the custom rubber flooring we provide or contact us for a quote.

Materials and Manufacturing

Custom rubber flooring can be made of nitrile, styrene-butadiene (SBR), polyurethane (PU), polyvinyl chloride (PVC), silicone, or other elastomers. Compound selection depends on your application requirements, so ask us which material has the properties and price point that you need. Typically, rubber floor mats are made of foam rubber rather than solid rubber. That’s because foam rubber is lightweight, impact resistance, and provides a measure of thermal and acoustic insulation.

For applications that require greater resistance to heat and noise, rubber flooring can be laminated to thermal and acoustic materials. By laminating materials with different properties into a sandwich-style structure, Elasto Proxy can create custom solutions that meet multiple requirements. In a heavy equipment cabin, for example, a custom floor mat can absorb sounds, reduce the transmission of heat from the engine bay, protect metal subfloors, and reduce slip-and-fall hazards.

Whether you need floormats with or without insulation, Elasto Proxy uses water jet cutting to convert sheet or roll materials into custom products. There’s no metal tooling to wait for or pay for, and we can support you from rapid prototyping through low-to-medium volume manufacturing. Importantly, water jet cutting makes fine, fast cuts. That’s good news if you need rubber floor mats that can accommodate the arms gas of gas or brake pedals or bolt holes for cabin seats.

Colors, Patterns, Finish, and Features

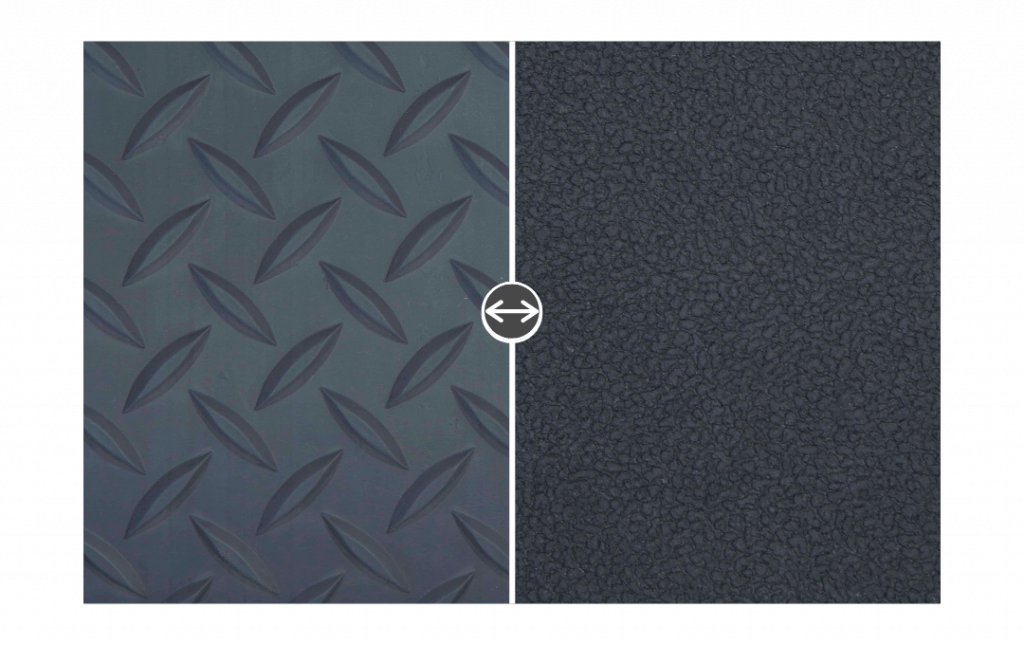

Most rubber floor mats are black, but Elasto Proxy can source flooring materials that are gray or brown, or that come in custom colors. Some rubber is smooth, but custom rubber floor mats can have a pebbled texture instead for slip-resistance. Custom rubber mats can also have a diamond plate (tread plate) to pattern catch the mud, snow, or water from a worker’s shoes or boots. By taking the time to understand all of your requirements, we can deliver greater value than you’d get from an off-the-shelf product.

Custom rubber flooring isn’t required for every application, but a standard product might not fit properly inside a heavy equipment cabin, food processing facility, commercial kitchen, or factory floor. Plus, some applications require flooring with specialized properties such as anti-microbial resistance, or the ability to withstand contact with harsh chemicals and abrasive substances. A standard rubber product might be cheaper but consider the cost of employee injuries or damage to facilities and equipment.

Custom Rubber Floor Mats from Elasto Proxy

Elasto Proxy makes custom rubber mats for commercial and industrial applications. We don’t sell directly to consumers, and we don’t make custom rubber floor mats for the owners of cars and light-duty trucks. If you’re a commercial or industrial buyer, however, we might have what you need. So, if the rubber flooring you need isn’t a commodity buy, ask us how can help.