Infrastructure

Infrastructure projects need sealing and insulation solutions that strengthen architectural designs. After all, buildings are more than just enclosed structures. They contain doors, windows, flooring, and lighting systems. Buildings also contain systems for HVAC, plumbing, electrical power, and fire protection. Together, all of these components are part of the facility’s infrastructure.

Builders, plumbers, electricians, and HVAC technicians need seals, gaskets, and insulation that are reliable, cost-effective, and easy-to-install. Compliance with building codes, regulations, and standards like NSF/ANSI 61 are also important. Sealing and insulation designers want to ensure quality, but there’s increasing pressure to do so at lower levels of cost. Technical buyers face challenges, too. If a supplier can’t deliver on-time, infrastructure projects may be delayed.

Elasto Proxy understands what your infrastructure projects need to succeed. Plus, we’re passionate about problem-solving. If an old seal won’t cover the gap in your new door or window, we’ll apply our technical expertise. If you need thermal-acoustic insulation for a retrofit, we’ll fabricate a custom “sandwich” from materials that handle high heat and loud sounds. We supply rubber matting for anti-slip flooring, too.

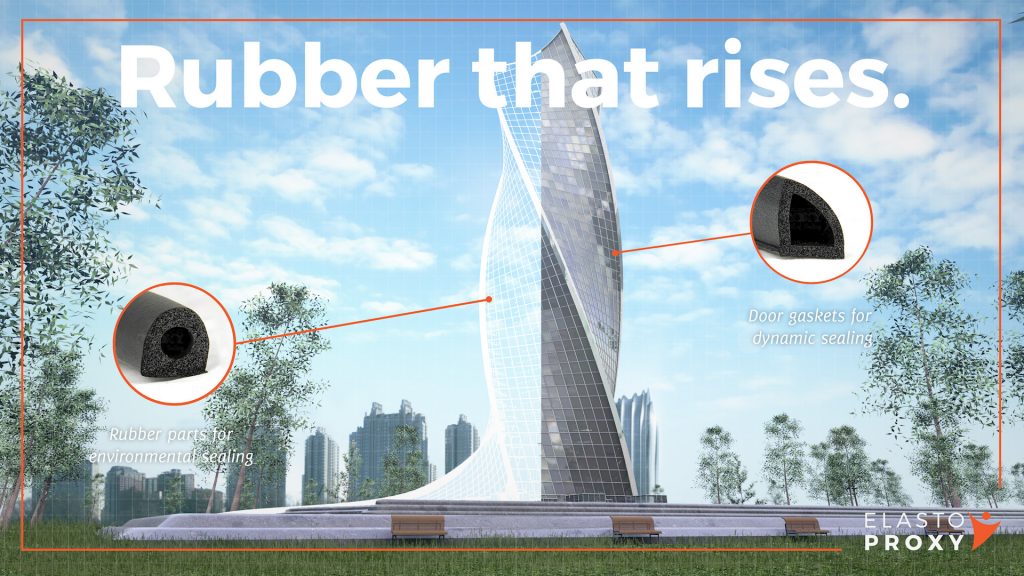

Elasto Proxy can also help you choose the right sealing materials for doors, windows, skylights, hatch covers, lighting fixtures, and custom plastic shims. Depending on your requirements, we may recommend EPDM gaskets, flame-retardant profiles, or ozone-resistant materials. We can also source molded rubber parts, dual-durometer extrusions, window channels, and weather-stripping. From hatch seals for HVAC systems to custom gate seals for water filtration systems, Elasto Proxy strengthens product designs.

With our application experience, Elasto Proxy also understands how different building materials interact. For example, rubber seals hold window glass in place and also contact metal window frames. When the sun’s rays strike then, it’s not just the glass that expands. Because changes in temperature cause changes in an elastomer’s length, area, and volume, product designers need a supply chain partner that understands the relationship between seal selection and thermal expansion.

Elasto Proxy also adds value to your projects through custom-fabrication. Our water jet cutter makes fine, fast cuts without tooling charges. Our skilled production personnel bond gasket corners with accuracy and precision. The taped gaskets that we supply arrive ready-to-install, reducing your labor costs and speeding operations. Because we specialize in low-to-medium volume quantities, Elasto Proxy is the right choice for prototyping or production.

Yet Elasto Proxy isn’t just a provider of rubber seals, plastic parts, and composite materials. We’re a supply chain partner whose expertise includes inventory management and logistics. After Elasto Proxy custom-fabricates your parts, we can store quantities in our U.S. or Canadian warehouses and then ship them to you on-demand or according to your sales forecasts. With our expertise in logistics, we’ll strengthen your infrastructure projects through on-time delivery.