Elasto Proxy provides rubber seals, foam handles, and plastic parts to manufacturers of hospital room equipment. Water jet cutting is ideal for polymers and elastomers in low-to-medium volume quantities.

Hospital patients with limited mobility face a variety of challenges. Routine tasks such as sitting up, getting out of bed, and bathing may require assistance from nurses or other hospital staff. Patient lifts and walk-in tubs support medical care, but hospital room equipment must be safe and reliable. Medical technology can help a 120-lb. nurse move or bathe a 300-lb. patient, but only with the right equipment design and high-quality components.

For manufacturers of hospital room equipment, implementing a strong product design means choosing a component supplier with care. Elasto Proxy, an experienced provider of low-to-medium volume quantities of rubber seals and plastic parts, supports your equipment designs through high-quality custom fabrication. That’s why manufacturers of walk-in tubs and patient lifts depend on us for safe, reliable parts. As the following examples show, Elasto Proxy is ready to meet your requirements.

Rubber Seals for Walk-in Tubs

Walk-in tubs make bathing safer and easier for hospital patients. Different door designs and installation configurations are available, and some walk-in tubs incorporate hydrotherapy options such as whirlpools or water jets. Walk-in tubs with LED lighting are also available. Regardless of product specifications and features, walk-in bathtubs need well-designed doors with reliable rubber seals. Otherwise, water may leak onto nearby flooring and pose a slip-and-fall hazard for patients and medical staff.

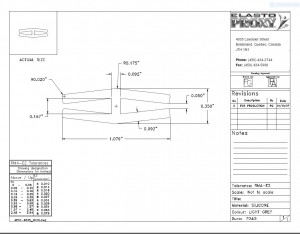

When a manufacturer of walk-in bathtubs needed a sealing solution, Elasto Proxy custom-fabricated gaskets made from silicone, a synthetic rubber with the ability to repel water and form watertight seals. Using our water jet cutting machine, Elasto Proxy’s skilled production personnel cut silicone extrusions with speed and precision. There are no dies or tooling charges, and water jet cutting won’t put pressure on rubber profiles. This fabrication technique also supports prototyping that’s fast and cost-effective.

Foam Handles and Plastic Parts for Patient Lifts

Water jet cutting is ideal for elastomers, but it’s also great for foam and plastic. Components made of these materials are used in patient lifts, hospital room equipment that helps people with

limited mobility to sit up or get up. Because patient lifts are powered, they also help smaller nurses to move larger patients. Some patient lifts are ceiling mounted, but others have wheels or casters. Depending on the design, a patient lift can help a person to get out of bed and safely enter or exit a walk-in tub.

When a manufacturer of patient lifts needed foam and plastic parts, Elasto Proxy applied its water jet cutting expertise. This patient lift featured a stainless steel tube with plastic caps and slide-on foam handles. A metal tube can support a patient’s weight, but stainless steel is hard, cold, and sometimes slippery. Plus, the ends of metal tubes may have small, sharp burrs. The slip-on foam handles and plastic caps that Elasto Proxy supplied were cut precisely, delivered on-time, and easy to assemble onto the tube.

How Can We Help You with Hospital Room Equipment?

Do you need rubber seals for walk-in bathtubs, or foam handles and plastic caps for patient lifts? For over 25 years, Elasto Proxy has supplied low-to-medium volume quantities of custom-fabricated components to a variety of industries. As this case study shows, we have the application knowledge and technical expertise to meet the needs of hospital room equipment suppliers.

Elasto Proxy’s capabilities also include a strong network of partners and logistical expertise. Additional examples of our work with the healthcare industry include plastic parts for hospital beds. By working with a plastic molder, we sourced parts for multiple designs, inspected them upon delivery, stored them in our warehouse, and released them according to the customer’s sales forecast.

Learn more about how Elasto Proxy supports medical and healthcare applications. Contact us.