Elasto Proxy custom-fabricates EMI gaskets from nickel-graphite filled silicones that contain an inner layer of conductive fabric for added strength and thinner designs.

Elasto Proxy custom-fabricates EMI gaskets from nickel-graphite filled silicones that contain an inner layer of conductive fabric for added strength and thinner designs.

Some electronic designs need EMI gaskets that balance physical strength with support for thinner devices. Conductive elastomeric shielding gaskets are a proven technology, but some design engineers worry that shielding silicones are packed with so many particles that these elastomers are brittle and will tear easily. Other engineers believe that particle-filled shielding elastomers are too thick, and can’t support electronic products with thinner profiles. These concerns are important ones, but Elasto Proxy can address them by fabricating EMI gaskets from nickel-graphite shielding silicones that are reinforced with conductive fabric.

Particle-Filled Silicones and Cost-Effective EMI Gaskets

As the first article in this series about EMI shielding explains, Elasto Proxy custom-fabricates gaskets made from particle-filled silicones that meet the U.S. military’s MIL-DTL-83528 specification. M83528, as this MIL-SPEC is better known, defines shielding and sealing requirements for EMI connector gaskets used in some military electronics. In addition to EMI shielding and environmental sealing, M83528 gaskets provide electrical conductivity. These attributes are important, but they don’t apply to consumer electronics. Moreover, not all military devices require M83528 materials or even QPL connector gaskets.

To provide EMI shielding and electrical conductivity, silicones are filled with metal or metal-coated particles. Historically, military drawings and blueprints have specified silver as the fill material. Silver is expensive, however, and subject to price fluctuations that can cause gasket costs to soar over time. An EMI gasket that costs $100 today could cause many times that amount next year. Elasto Proxy can custom-fabricate EMI connector gaskets that are filled with pure silver, but we can also provide EMI gaskets that are filled with less expensive silver-coated or nickel-coated particles.

Nickel-Graphite Silicones With Conductive Fabric Reinforcements

![]() Shielding silicones that contain nickel-coated graphite particles aren’t just cost-effective. They provide strong EMI shielding and reliable environmental sealing for applications such as military touchscreens that do not require M83528 materials. They’re also suitable for consumer electronics and other civilian applications. Moreover, these nickel-graphite filled silicones can be reinforced with an inner layer of conductive fabric that enhances material strength. This addresses engineers’ concerns that packing a silicone with particles makes the elastomer too brittle, and thus prone to tearing.

Shielding silicones that contain nickel-coated graphite particles aren’t just cost-effective. They provide strong EMI shielding and reliable environmental sealing for applications such as military touchscreens that do not require M83528 materials. They’re also suitable for consumer electronics and other civilian applications. Moreover, these nickel-graphite filled silicones can be reinforced with an inner layer of conductive fabric that enhances material strength. This addresses engineers’ concerns that packing a silicone with particles makes the elastomer too brittle, and thus prone to tearing.

Tearing is also an important concern for the gasket fabricator. When a material lacks sufficient tensile strength, cutting a small part with a thin cross-section may result in tearing during packaging or application. With more expensive compounds, both the gasket fabricator and the engineer are especially concerned about maximizing material yield and minimizing material waste. At the same time, a tear can cause the loss of a conductive seal and allow the entry of radio frequency (RF) waves that can cause electronic interference.

Strong, Thin EMI Gaskets from Elasto Proxy

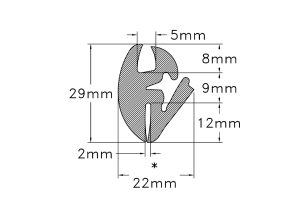

To address these challenges, Elasto Proxy custom-fabricates EMI gaskets from nickel-coated graphite-filled silicones that contain an inner layer of conductive fabric. These 65-durometer elastomers have a volume resistivity – an indirect measure of EMI shielding effectiveness – that’s similar to silicones that contain more expensive silver or silver-coated particles. The conductive fabric reinforcement also imparts superior properties. The table below explains.

| Data | Typical Values |

| Durometer (Shore A) | 65 |

| Tensile Strength (psi) | 950 |

| Elongation % | 20 |

| Tear B @ 35 minutes (ppi) | 165 |

| Specific Gravity | 1.93 |

| Thickness (0.017-0.023 inches) | 0.020 inches |

| Volume Resistivity (ohm/cm) | 0.007 ohm/cm |

| Compression Set % | 70 hrs @ 100° C | 25 |

| Standard Color | Dark Gray |

| Thermal Stability Range | -55° C to +200 ° C |

How Can We Help You?

Would you like to learn more about nickel-graphite silicones with conductive fabric reinforcements for EMI connector gaskets? Would you like to talk to our solutions providers about how Elasto Proxy can use water jet cutting, bonding, and taping to meet your application requirements? For over 25 years, we’ve been supplying the North American defense industry with sealing and insulation solutions. Contact us on-line for more information, or visit us at CANSEC 2016 in Booth #935.