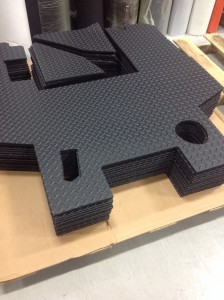

Forestry Equipment Rubber Cab Parts

In this case study, you’ll learn how Elasto Proxy used water jet cutting to fabricate cost-effective parts for forestry equipment. From prototyping to production, water jet cutting is meeting the requirements of a leading mobile equipment manufacturer.

Forestry equipment such as log skidders, feller bunchers, forwarders, delimbers, and harvesters are built for off-road conditions. Steep terrain, mud, and snow won’t stop these wheeled or tracked machines when they’re driven by skilled operators. Cab safety and comfort matters, too, and equipment owners recognize the importance of protecting personnel and machinery. That’s why when buyers compare forestry equipment, they reward manufacturers that meet demanding requirements.

The big diesel engines that power forestry equipment are loud, but dampening engine noise isn’t just about operator comfort. Noisy machinery can cause hearing loss, affect worker safety, and result in violations that carry fines and other penalties. Loud, unwanted noises can also affect buyer perceptions about equipment quality. Yet engine sounds aren’t the only reason for cab sealing and insulation. Mud or snow from an operator’s boots gets tracked into the cab, and water can pool or freeze on the floor. (more…)

In this case study, you’ll learn how Elasto Proxy helped a manufacturer of hospital beds to reduce costs, promote patient safety, and meet regulatory requirements. By applying the power of our supply chain strength, Elasto Proxy provides plastic parts that replace metal ones.

In this case study, you’ll learn how Elasto Proxy helped a manufacturer of hospital beds to reduce costs, promote patient safety, and meet regulatory requirements. By applying the power of our supply chain strength, Elasto Proxy provides plastic parts that replace metal ones.